clamp on ultrasonic flow meter installation guidelines

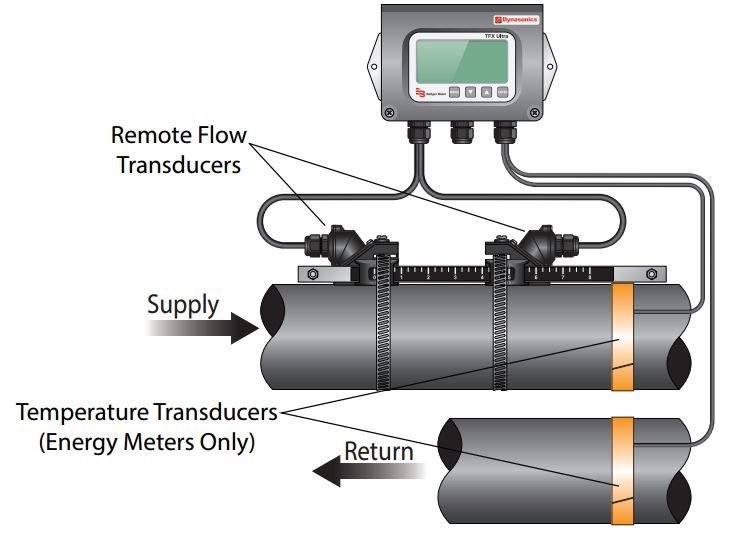

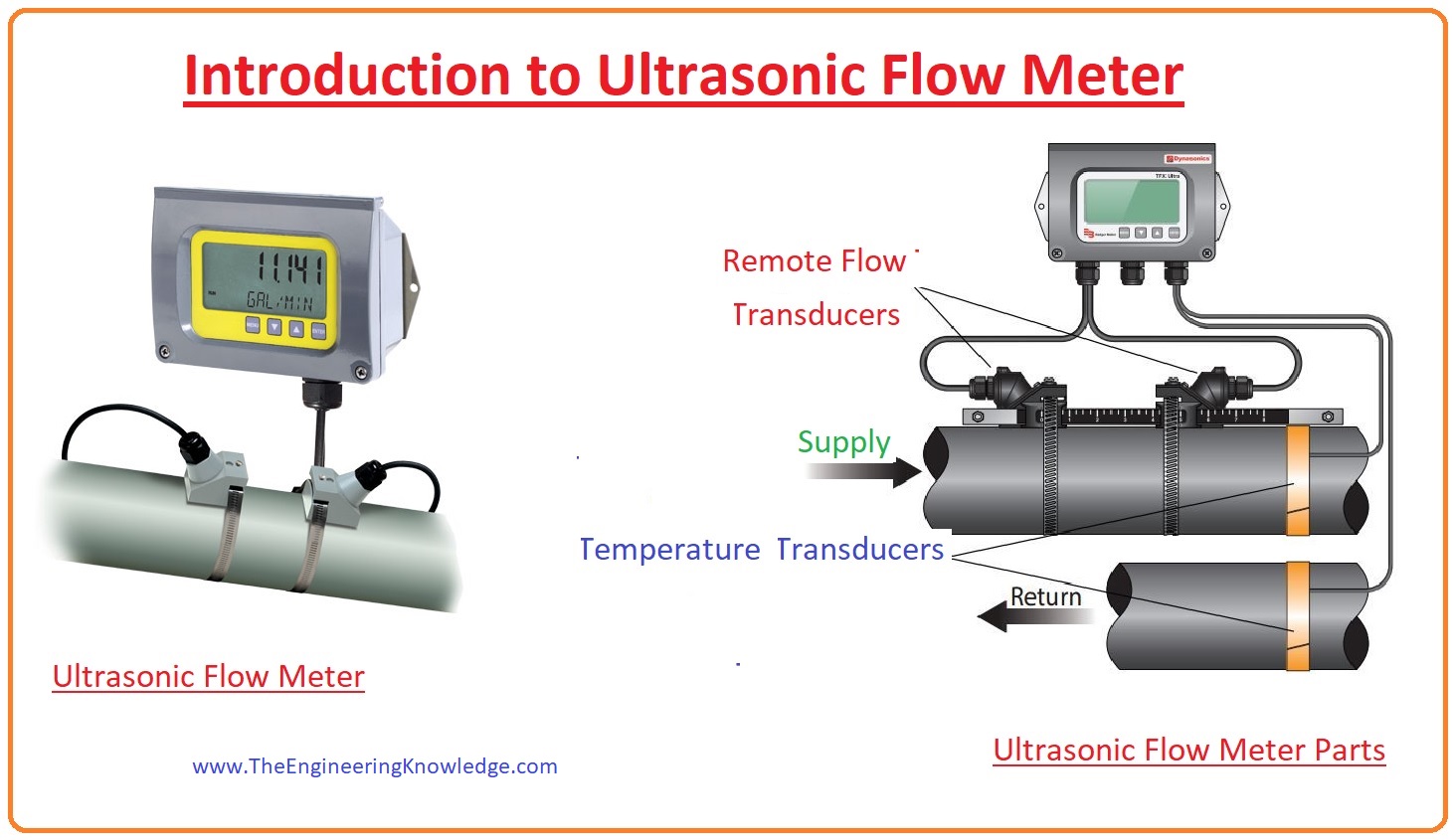

Suitable for most pipe materials with diameters from 6 mm to 65 m 14 to 256 Multi Channel Ultrasonic Flowmeter Configurable process inputsoutputs 04. The F-4300 Ultrasonic Flow Meter utilizes clamp-on signal transducers that mount on the outside wall of the pipe.

Ultrasonic Water Flow Meter Gaimc Group

KEYENCEs FD-R Series Clamp-on Flow Meter is designed for pipes as large as 8.

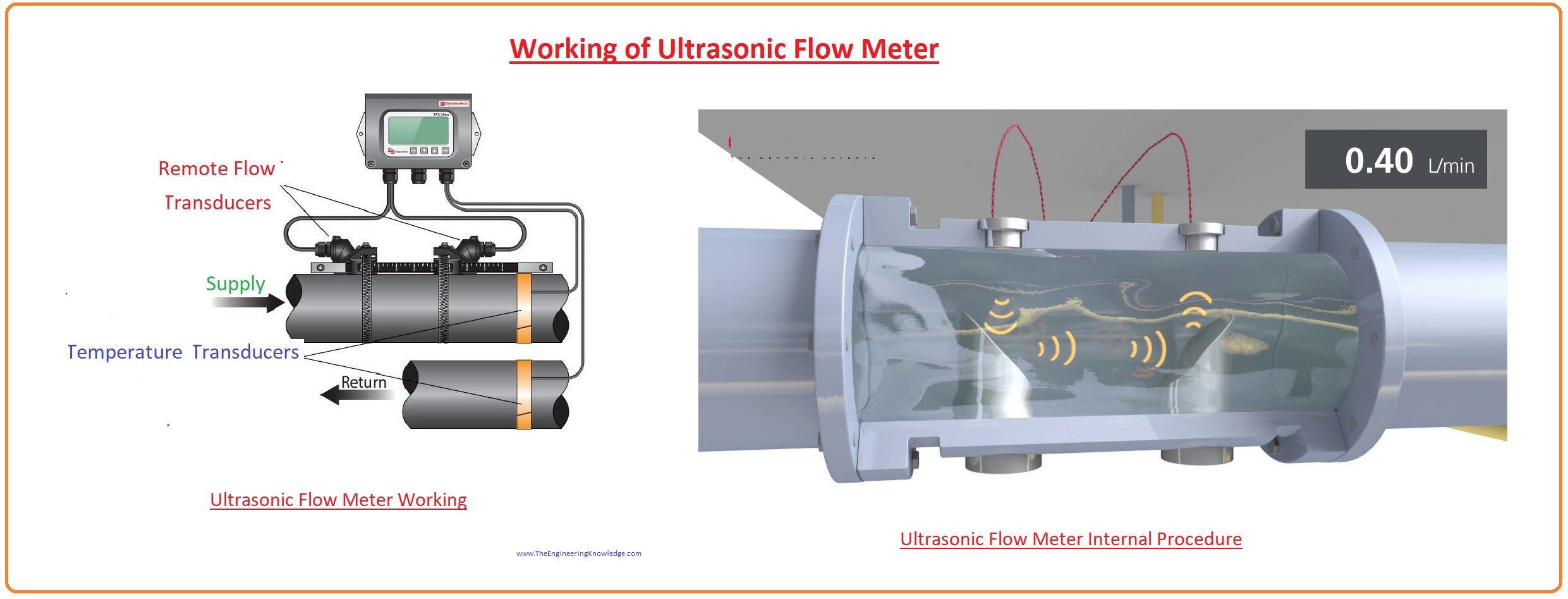

. The installation of mostly proven invasive flow measurement technology results in necessary pipe openings and temporary process interruptions. Ultrasonic flowmeter is a non-contact instrument which can measure the flow of medium with large diameter and can also be used for the measurement of medium that is not easy to contact and observe. As the ultrasonic sensors are simply clamped on the pipe surface Katronic ultrasonic flow meters can be installed without the need to break into pipelines.

It is suitable for measuring the volumetric flow of liquids in a wide variety of applications including bi-directional flow applications. Transit time ultrasonic flow meter send and receive ultrasonic waves between. The device can be mounted to a variety of materials including stainless steel iron copper PVC and resin.

Smart Ultrasonic and Electromagnetic WaterFlow Meter Manufacturing Emailfatihya-liupanda-groupcn Whatsapp8618758081475 Press J to jump to the feed. 20 mA relay contacts temperature etc The range of non-invasive flowmeters utilizes ultrasonic technology for the accurate flow measurement of liquids in full pipes. Flexim a globally recognized leader in the m.

The spacing value shown on menu window M25 refers to the distance of inner spacing between the two. Clamp On Ultrasonic Flow Meters Installation Guidelines Rms Engineering If enough grease is not applied or the transducers are not clamped to the wall tightly the precision of measurement may be effected. It is recommended to install the device with an angle of 120 degrees.

Browse our Equipment Guide categories to find and contact your manufacturer. With the recent high growth in the ultrasonic clamp on flow metering market many users are turning to this style of meter for quick and easy solutions for some difficult to measure fluid flow applications. Its measurement accuracy is very high and the external clip-type installation can reach the highest accuracy of 05.

It also adopts the current popular OLED display which makes it easy to read in low light conditions. The sensors are fixed to the pipe using metal chains straps or mounting rails. It is suitable for measuring the volumetric flow of liquids in a wide variety of applications including bi-directional flow applications.

Up to 15 cash back Clamp-on Ultrasonic Flow is a non-intrusive technology that is applied to the outside of process piping. The meter is housed in an aluminum enclosure with silicone. In case of horizontal piping mount the detector within 45 from.

FHM500 is very unique in its structural design. Ideal for clean liquid applications this transit-time measurement technology reduces installation downtime and provides significant cost effectiveness when compared to inline flow measurement equipment especially in larger pipe sizes. 12 TYPICAL FP-4400 FLOW METER INSTALLATION The FP-4400 Portable Clamp-on Ultrasonic Flow Meter utilizes clamp-on signal transducers that mount on the outside wall of the pipe.

Keep appropriat e clearance on either side of the pipe for easy transducer installation. Press question mark to learn the rest of the keyboard shortcuts. It takes only 2-3 minutes to complete the whole process from installation to measurement.

Both flow and temperature monitoring is possible for a wide variety of liquidsfrom water including pure. Always install the sensor to an uninsulated part of the pipe. 15 cm if you are not using a.

For best results a vertical installation with flow in an upward direction is recommended. Ultrasonic Flow Meters HOW IS THE FLOW METER INSTALLED. Producing consistently accurate results with an ultrasonic flow meter depends heavily on a proper installation.

Remove any insulation if necessary. It uses a circular magnetic steel to achieve automatic connection during installation. Locate the transducer measurement point at least 3 ft 1 m from any butt welds or flanges ideally in the center of a 20 ft 6 m length of straight run of pipe.

Ultrasonic flow meter installation guidelines Steps to the installation of the transducers. Pipe type ultrasonic flow meter. Silver Automation Instruments Limited provides SLH Series Ultrasonic Flow meter SLH Series ultrasonic flow meter is based on the principle of transit-time.

FHM500 is widely. Locate an optimal position where the straight pipe length is sufficient. Installation is easy and requires only a screwdriver.

Having conducted over 500 clamp-on. The meter is housed in a NEMA 4X IP67 polycarbonate wall-mounted enclosure with a built-in user. About 30 of these are magnetic flow meters and others are turbine vortex ultrasonic and mass flow meters.

Installation Guidelines Mount the sensor guide to at least 10 DN downstream of a flow disorder such as elbows valves headers or pumps and at least 5 DN sockets after the device.

U1000mkii Fm Fixed Clamp On Ultrasonic Flow Meter Micronics

![]()

F 4300 Clamp On Ultrasonic Flow Meter Thermal Energy Measurement System Onicon Flow And Energy Measurement

Product Spotlight Flowmeters Processing Magazine

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

6000 Series Portable Ultrasonic Flow Meter

Clamp On Transit Time Ultrasonic Flow Meter

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

Portable Ultrasonic Flow Meter Installation Tutorial How To Solve No Signal Message Youtube

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

Ultrasonic Flow Meter The Engineering Knowledge

Clamp On Ultrasonic Flow Meter For 2 5 To 10 Pipes

Clamp On Ultrasonic Flow Meters Installation Guidelines Rms Engineering

Clamp On Ultrasonic Flow Meters Installation Guidelines Rms Engineering

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument